Email Us

info@salamco.com.pk

- PMS is a European product. Designed by a team of industrial engineers from garmenting industrial with an international experience of 20 years.

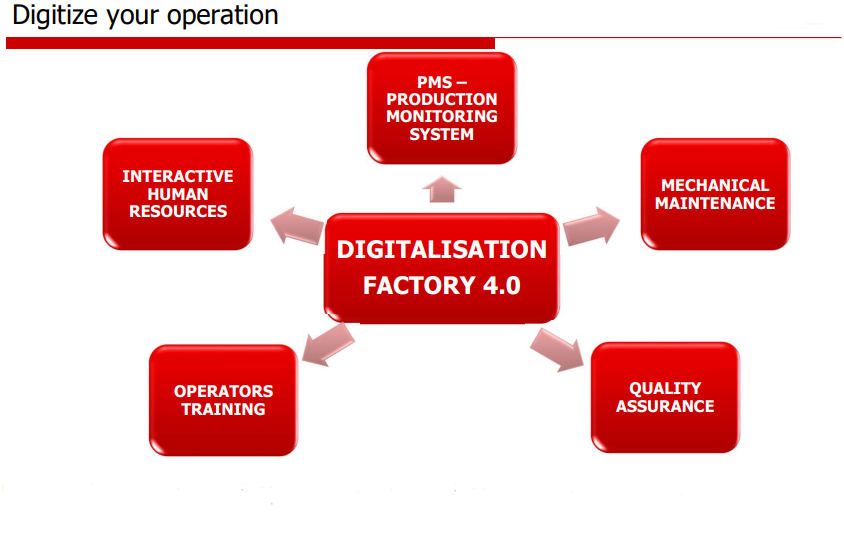

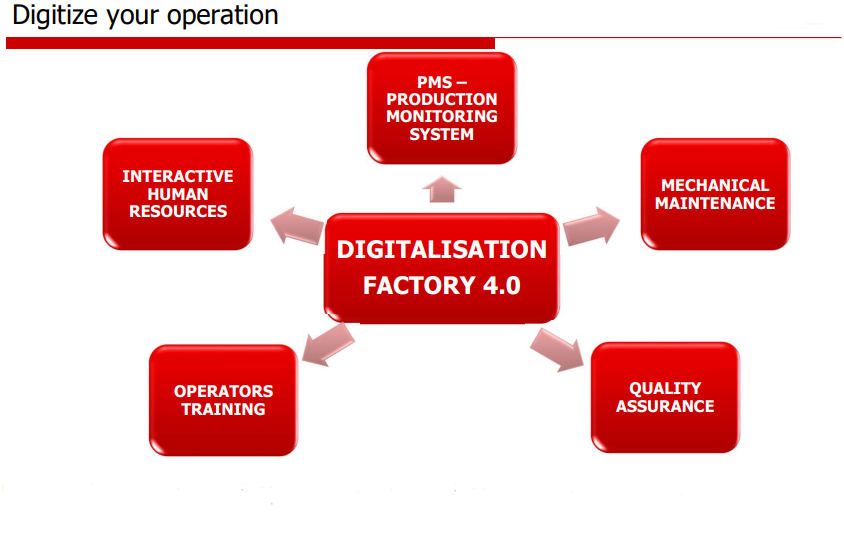

- Industry ‘4.0’ complete package including:

- Bundle tracking system.

- Nonproductive time of the operator.

- Quality assurance.

- Mechanical maintenance.

- ERP’s integration directly.

- Industrial Engineers.

- IoT connectivity with any brand of m/c & m/cs of any age.

- We guarantee 10% efficiency increase which gives ‘ROI’ of 1 year.

How PMS Works ?

-

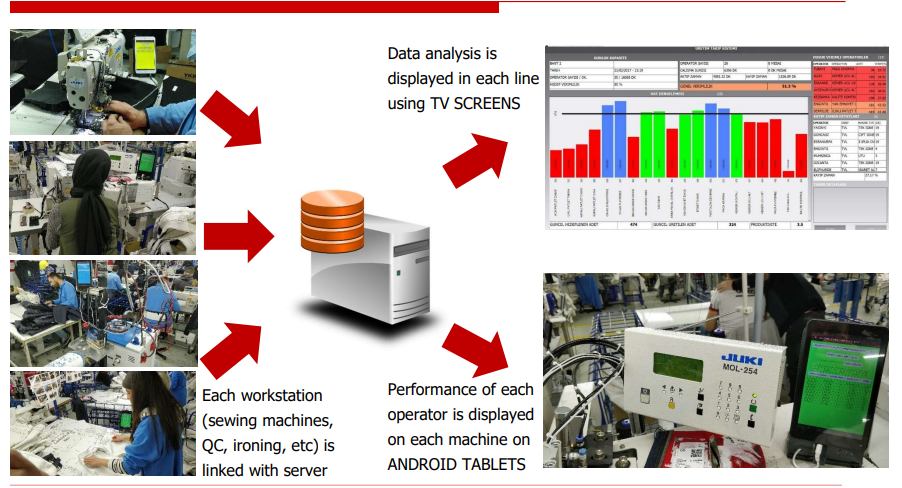

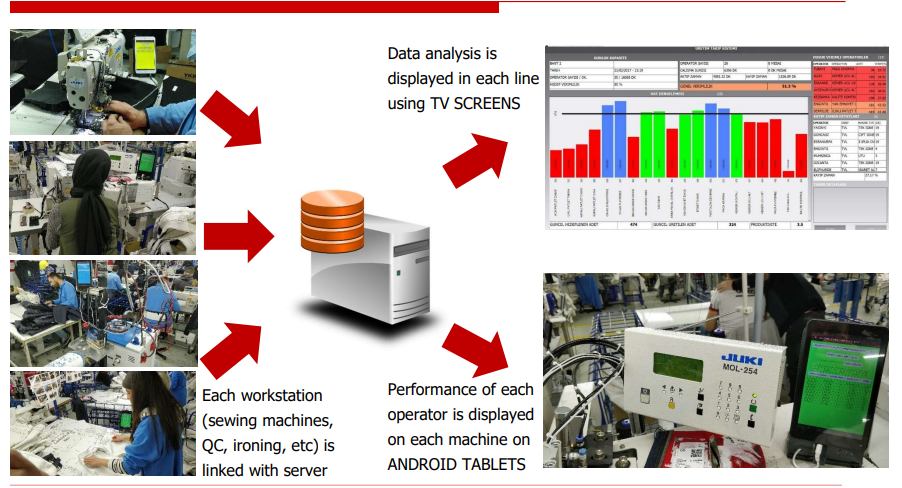

We are “scanning” the Sewing Machine activity either by connecting our software directly with the electronic of the machines (in case of new generation of machines) or through a special hardware able to “read” the machine activity

-

This apply for any kind of sewing machine, any brand, any age (from 20 years old machines to last generations) and any type of garmenting operation (sewing, ironing, Quality Control, manual operations).

-

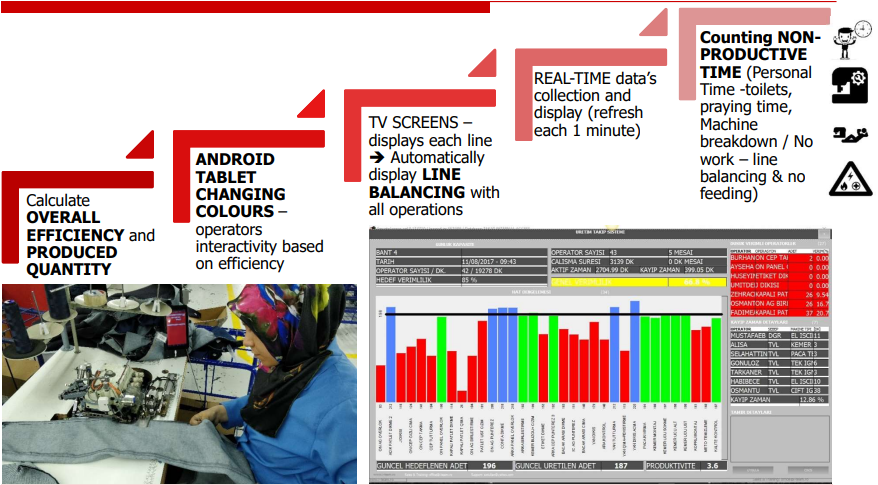

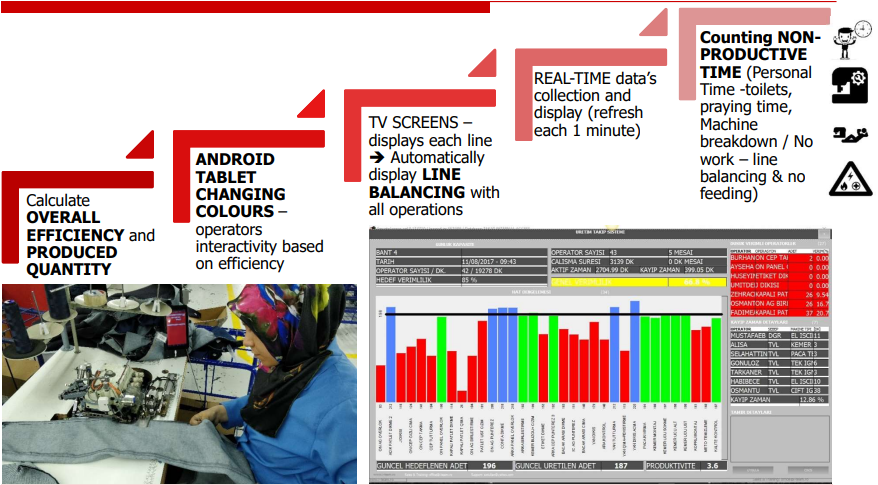

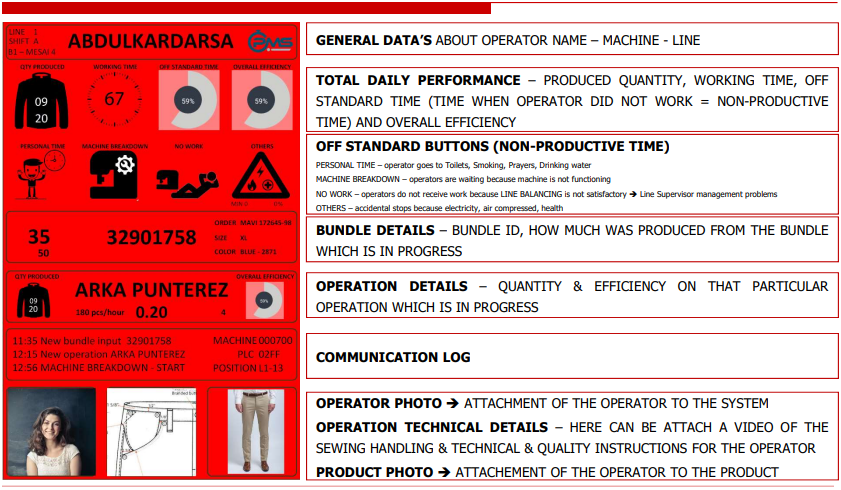

Centralized server, process all data’s and create analysis. Calculate ON STANDARD EFFICIENCY, OVERALL EFICIENCY, MACHINE BREAKDOWN TIME, TOTAL QTY PRODUCED, for each operator, each line and each factory; all calculations are refreshed every minute.

-

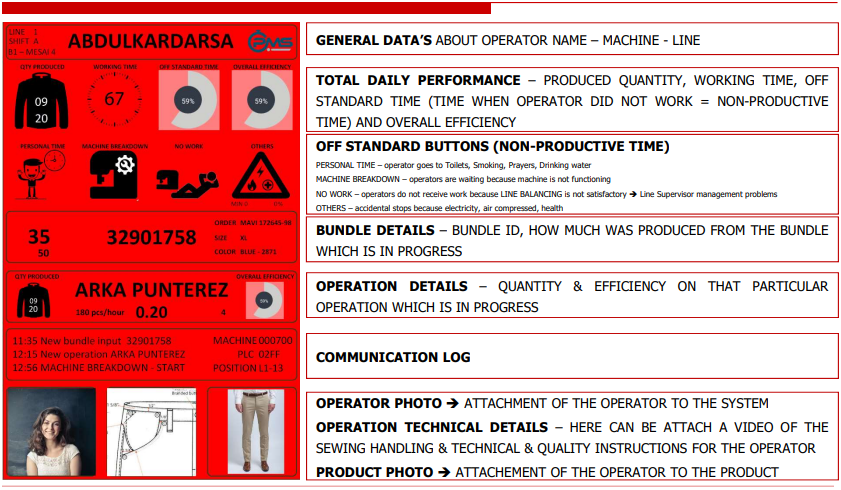

Each machine have a ANDROID TABLET which is the interface between operators and PMS software. TABLETS shows to operators what is their OVERALL EFFICIENCY, QTY PRODUCED, QUALITY PRODUCED all in REAL TIME refresh every minute.

-

Each sewing line have TV SCREENS showing CENTRALISED DATAS regarding performance of that specific line.

-

There is a optional development in progress - Artificial Intelligence separate module called SUPERVISOR ASSISTANT which once activated will create a LINE BALANCING analysis each 30 minutes, will calculate based on mathematical algorithm the actions that Line Supervisors have to do in the next 30 minutes in order to correct the line (stopping one operation, move operators to a new operation, bring a new machine in the line, etc). This messages will be displayed on the TV SCREENS and Supervisors can follow

Workstation/operator → server/software’s → ANDROID/TV SCREENS

PMS - Features

PMS – ANDROID Tables Interactivity with Operators

-

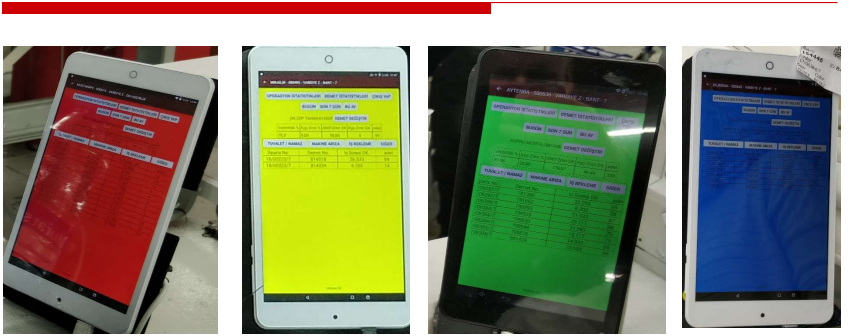

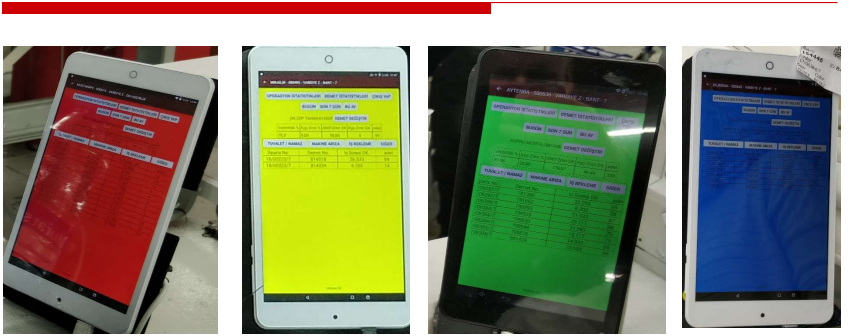

ANDROID Tablet is changing colors depend on OVERALL EFFICIENCY (under 65% - RED / 65-85% - YELLOW / 85-100% - GREEN / over 100% - BLUE → strong VISUAL FEED_BACK.

-

Tablet shows NON-PRODUCTIVE TIME to each operator operator is aware about his time losses

-

Tablet shows QUALITY DEFECTS → REAL-TIME feed-backs directly to operator